In the ever-evolving landscape of global commerce, effective supply chain management stands as a cornerstone of organizational success. At the heart of this management paradigm lies Enterprise Resource Planning (ERP), a robust system designed to integrate and streamline core business processes across various departments. Within the realm of supply chain management (SCM), ERP supply chain plays a pivotal role in orchestrating the flow of goods, information, and finances, thereby optimizing efficiency and enhancing organizational agility.

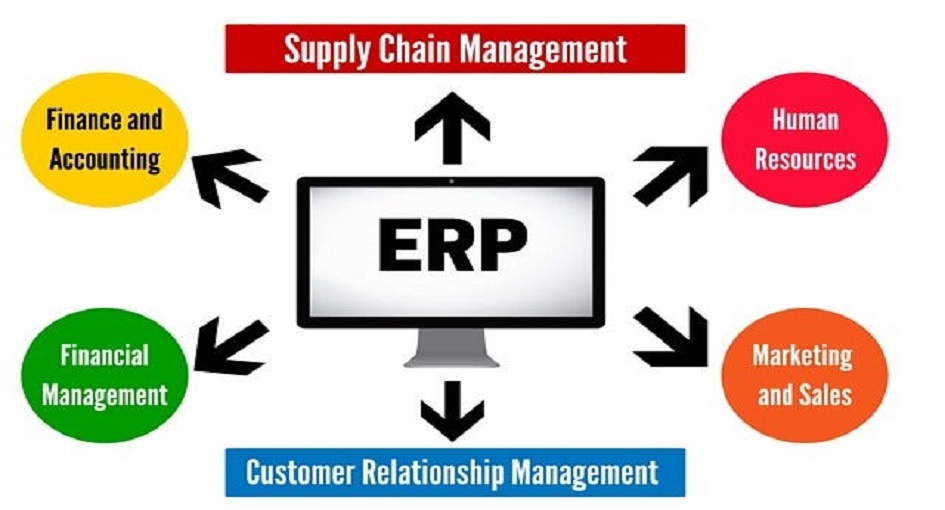

ERP systems encompass a suite of integrated applications that enable seamless coordination and communication across an organization’s supply chain network. From procurement and production to distribution and customer service, ERP supply chain consolidates disparate functions into a unified platform, fostering operational synergy and driving strategic alignment with business objectives.

Central to the discussion is the profound impact of ERP on enhancing supply chain transparency and collaboration. Transparency, in this context, refers to the accessibility and visibility of critical data and insights throughout the supply chain continuum. By centralizing data repositories and providing real-time analytics, ERP empowers stakeholders with actionable intelligence, enabling informed decision-making and proactive management of supply chain dynamics.

Collaboration, on the other hand, epitomizes ERP’s capability to facilitate seamless interaction and cooperation among internal teams, external partners, and suppliers. Through integrated communication channels and shared information repositories, ERP bridges operational silos, fosters cross-functional collaboration, and nurtures strategic alliances that drive innovation and responsiveness in the marketplace.

Moreover, ERP supply chain systems are instrumental in navigating the complexities of modern supply chains, characterized by globalized sourcing, just-in-time inventory management, and stringent regulatory compliance. By automating routine tasks, optimizing resource allocation, and enhancing supply chain visibility, ERP mitigates operational risks, reduces lead times, and bolsters supply chain resilience in the face of disruptions. As organizations increasingly embrace digital transformation initiatives. What is the role of ERP in supply chain management becomes even more pronounced.

Enterprise Resource Planning (ERP) systems integrate core business processes, including finance, manufacturing, inventory management, and human resources, into a unified platform. In the context of supply chain management (SCM), ERP extends its functionality to streamline and optimize the flow of goods, information, and finances across the entire supply chain network. By consolidating data and processes into a centralized system, ERP enhances visibility, efficiency, and decision-making capabilities throughout the supply chain.

One of the primary benefits of ERP in supply chain management PDF is its ability to enhance transparency. By providing real-time access to critical data such as inventory levels, production schedules, and order status, ERP systems enable stakeholders to make informed decisions promptly. This transparency not only improves operational efficiency but also facilitates proactive management of supply chain disruptions and reduces lead times.

Collaboration is essential for optimizing supply chain performance, and ERP supply chain systems facilitate seamless collaboration among internal departments, suppliers, and customers. Through features like electronic data interchange (EDI) and supplier portals, ERP enables secure communication and information sharing across the supply chain ecosystem. This collaborative approach fosters stronger relationships, improves responsiveness to market changes, and supports innovation in product development and customer service.

Modern ERP systems offer a range of features tailored to meet the specific needs of supply chain management. These include:

Optimizing inventory levels to prevent stockouts and minimize carrying costs.

Using historical data and predictive analytics to forecast demand accurately.

Streamlining warehouse operations through automated workflows and real-time tracking.

Managing supplier interactions, performance, and contracts to ensure reliability and consistency.

Enhancing transportation planning and execution for efficient order fulfillment.

Several organizations have successfully implemented ERP systems to transform their supply chain operations. For instance, global giants like Amazon and Walmart leverage ERP to manage vast inventories, coordinate logistics, and deliver products efficiently to customers worldwide. Smaller enterprises also benefit from ERP solutions tailored to their scale and industry requirements, demonstrating the versatility and scalability of ERP in diverse supply chain environments.

While ERP systems offer significant advantages, their implementation can present challenges. These include high upfront costs, complexity in integrating legacy systems, and resistance to change among employees. Effective change management and thorough planning are essential to mitigate these challenges and maximize the ROI of ERP investments.

While the difference between ERP and SCM are closely related, they serve distinct purposes within an organization’s operations. ERP focuses on integrating core business functions across departments, whereas SCM emphasizes the management of external relationships and logistics to optimize the supply chain’s efficiency. Integrating ERP with SCM solutions enhances synergy between internal processes and external supply chain activities, driving overall operational excellence and customer satisfaction.

Choosing the right ERP system is crucial for achieving supply chain transparency and collaboration. Leading ERP providers like SAP, Oracle, and Microsoft Dynamics offer robust solutions tailored to the complexities of supply chain management. Factors such as scalability, industry-specific functionality, cloud readiness, and support for emerging technologies (like AI and IoT) influence the selection of the best ERP system for an organization’s supply chain needs.

The adoption of ERP systems has created a demand for skilled professionals who can manage, implement, and optimize ERP solutions within supply chain environments. Roles such as ERP consultant, supply chain analyst, business process analyst, and ERP project manager are critical in driving ERP initiatives and ensuring alignment with organizational goals. Certifications and specialized training in ERP systems enhance career prospects in this dynamic field.

ERP systems ensure data accuracy and integrity by centralizing information across departments and eliminating redundant data entry. This reliability enhances decision-making processes and reduces the risk of errors in supply chain operations.

The integration of real-time reporting and analytics capabilities in ERP supply chain systems enables stakeholders to access actionable insights promptly. By analyzing key performance indicators (KPIs) such as on-time delivery rates and inventory turnover, organizations can identify areas for improvement and optimize supply chain processes proactively.

ERP systems support compliance with regulatory requirements and industry standards by enforcing consistent processes and documentation across the supply chain. Additionally, ERP enhances risk management strategies by identifying potential risks, such as supplier disruptions or regulatory changes, and facilitating timely mitigation actions.

What is an ERP supply chain?

ERP supply chain integrates all supply chain management facets into a unified system, optimizing goods, information, and finances. This enhances transparency, coordination, efficiency, decision-making, reduced operational costs, and increased market agility.

What does ERP stand for in logistics?

ERP is a logistics software system that streamlines key business processes like procurement, inventory, order fulfillment, transportation, and distribution, enhancing efficiency, transparency, and collaboration across the entire logistics network.

What is the difference between ERP and SAP?

SAP, a leading provider of ERP software, is known for its comprehensive and scalable solutions, specifically designed for data processing. ERP systems integrate core business processes across organizations, such as finance, HR, manufacturing, and procurement, ensuring efficient and effective data management.

What is CRM and ERP?

CRM and ERP are essential business management systems, with CRM focusing on customer interactions and sales growth, and ERP automating core processes across departments for efficiency and performance analysis. Both systems serve different purposes.

Is Salesforce an ERP or CRM?

Salesforce is a CRM system primarily focused on customer interactions, offering ERP-like features but focusing on CRM capabilities, rather than broader ERP functions like financial management and inventory control.

ERP systems facilitate comprehensive supplier performance monitoring by tracking metrics such as delivery lead times, quality standards, and cost efficiencies. This visibility enables organizations to nurture strategic supplier relationships, negotiate favorable terms, and maintain a competitive edge in the market.

Integrating ERP with CRM systems enables seamless communication and collaboration between sales, marketing, and supply chain teams. By sharing customer insights and order information, organizations can enhance customer satisfaction, optimize demand forecasting, and align supply chain activities with customer expectations.

ERP systems contribute to supply chain resilience by enabling organizations to adapt quickly to disruptions, such as natural disasters or geopolitical events. By simulating scenarios and modeling alternative supply chain strategies, ERP enhances agility and ensures continuity in operations.

Modern ERP systems support sustainability initiatives by optimizing transportation routes, reducing carbon emissions, and promoting responsible sourcing practices. By monitoring environmental metrics and implementing green supply chain strategies, organizations can minimize their ecological footprint and enhance their brand reputation.

Investing in ERP supply chain training and skill development programs empowers employees to leverage ERP functionalities effectively. By fostering a culture of continuous learning and proficiency, organizations can maximize the benefits of ERP systems and drive innovation in supply chain management practices.

Highlighting real-world examples and success stories of organizations that have implemented best ERP for supply chain management can provide valuable insights and practical learning. Case studies demonstrate how ERP systems have transformed operations, improved collaboration, and achieved measurable business outcomes in diverse industry sectors.

The convergence of ERP with emerging technologies such as the Internet of Things (IoT), artificial intelligence (AI), and blockchain is poised to revolutionize supply chain management. These innovations promise enhanced automation, predictive analytics, and transparency, paving the way for more agile, efficient, and sustainable supply chains in the future.

ERP systems enable robust traceability across the supply chain by tracking raw materials, components, and finished products throughout their lifecycle. This capability supports compliance with regulatory requirements, enhances product safety, and facilitates recalls or audits when necessary.

Integrating ERP with maintenance management systems enables predictive maintenance of critical assets. By analyzing equipment performance data and scheduling proactive maintenance tasks, organizations can minimize downtime, optimize asset utilization, and extend asset lifecycles.

ERP systems provide global supply chain visibility by consolidating data from multiple locations and international suppliers into a unified platform. This visibility enables organizations to monitor inventory levels, manage cross-border logistics, and adapt strategies to local market conditions.

ERP systems support continuous improvement initiatives and lean manufacturing practices by identifying inefficiencies, reducing waste, and optimizing production processes. By integrating lean principles with ERP functionalities, organizations can achieve operational excellence and meet customer demand efficiently.

ERP facilitates collaborative forecasting and demand planning by enabling cross-functional teams to share data, insights, and forecasts in real-time. This collaboration improves accuracy in predicting customer demand, optimizing inventory levels, and reducing supply chain variability.

ERP systems streamline quality management processes by standardizing quality control measures, conducting inspections, and managing non-conformances. This ensures adherence to quality standards, certifications (such as ISO), and regulatory requirements throughout the supply chain.

ERP systems support integration with third-party logistics providers (3PLs) to enhance supply chain flexibility and scalability. By exchanging data seamlessly with 3PLs, organizations can optimize transportation management, reduce logistics costs, and improve delivery performance.

Ensuring cybersecurity and data protection is critical when implementing ERP systems in supply chain management. ERP platforms incorporate robust security measures, such as encryption, access controls, and regular audits, to safeguard sensitive information and mitigate cyber threats.

The adoption of mobile ERP applications facilitates real-time collaboration among supply chain stakeholders, regardless of their location. Mobile access to ERP functionalities empowers employees to make informed decisions, respond to changes promptly, and maintain productivity on the go.

ERP systems support ethical sourcing and supply chain transparency by tracking suppliers’ adherence to social responsibility standards, labor practices, and ethical guidelines. This transparency strengthens corporate social responsibility initiatives and enhances the brand’s reputation.

Looking ahead, advancements in ERP technology are poised to reshape supply chain management. Key trends include the integration of AI and machine learning for predictive analytics, blockchain for enhanced traceability and transparency, and the adoption of ERP systems in agile and decentralized supply chain networks. These innovations promise to further improve efficiency, resilience, and sustainability across global supply chains.

With this in mind, ERP supply chain systems play a transformative role in enhancing supply chain transparency and collaboration. By integrating business processes, optimizing workflows, and fostering communication across the supply chain ecosystem, ERP enables organizations to achieve operational excellence and respond effectively to market dynamics. As technology continues to evolve, embracing ERP solutions tailored to supply chain management will be essential for organizations seeking to maintain competitiveness and drive innovation in the digital age.